Why Pre‑Qualification Questionnaires Matter in UK Construction

Summary

Discover why pre‑qualification questionnaires (PQQs) are critical in UK construction procurement, what they include, and how automation boosts supplier compliance.

What Is a PQQ?

- Financial stability

- Health & Safety competence

- Environmental management

- Quality assurance

- Insurances and certifications

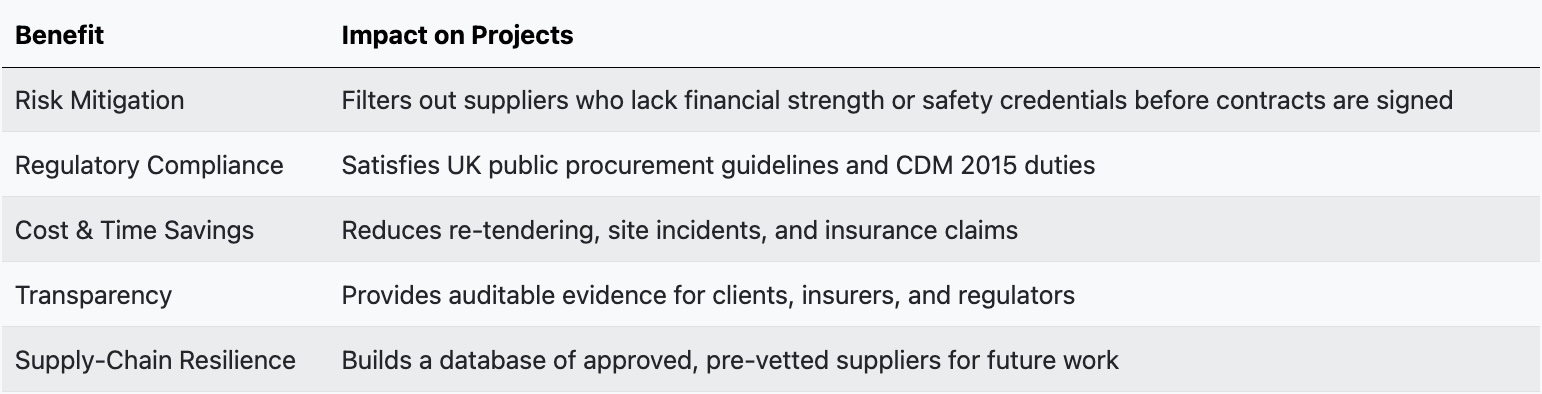

Why Do PQQs Matter in UK Construction?

Key Components of a Construction PQQ

- Business Identity & Standing – Company registration, ownership, references.

- Financial Performance – Turnover, profit margin, insurances.

- Health & Safety – Policies, accident records, SSIP certificates.

- Environmental Controls – ISO 14001 or equivalent evidence.

- Quality Management – ISO 9001 or internal QA procedures.

- Equal Opportunities & Diversity – Policies and training logs.

- Optional Modules – BIM capability, modern slavery, CSR initiatives.

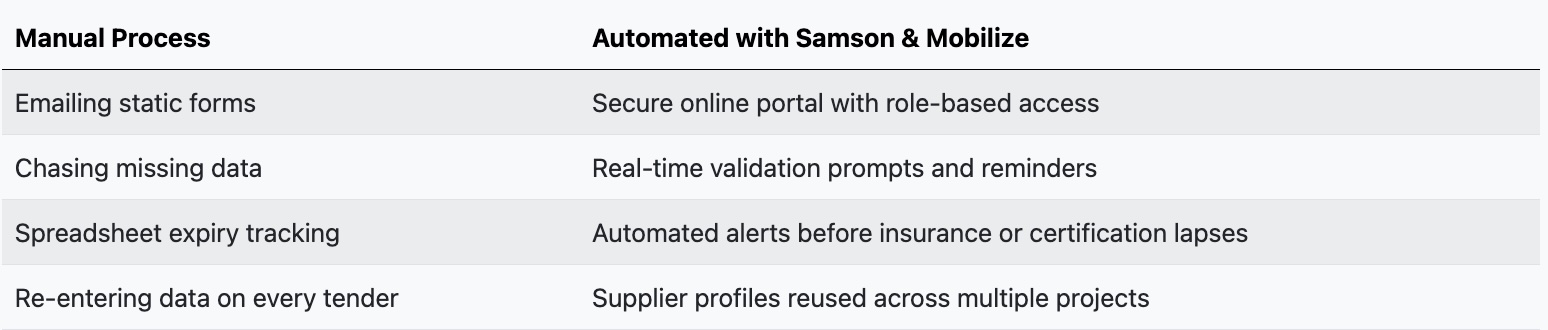

How Automation Improves Supplier Compliance

Manual PQQ workflows simply can’t keep pace with modern project timelines. Platforms like Samson by Liaison Systems digitise the entire journey:

Free PAS-91 Checklist

We have created a simple checklist based on the British PAS-91 standard to help you to build a pre-qualification questionnaire that will both reduce supply chain risk and ensure you're procuring quality suppliers.

Frequently Asked Questions

Conclusion: Build Strong Projects on Solid Compliance

A thorough pre‑qualification questionnaire construction strategy cuts risk, boosts transparency, and accelerates mobilisation. Combine that with automation and you gain a competitive edge: projects start sooner, data stays current, and compliance is never in doubt.Mobilize

Supply Chain Management

Mobilize offers a fully customisable suite of tools designed to help you manage your entire supply chain with precision giving you complete visibility and control so that you can reduced risk at every stage, from onboarding through to project review.

Related articles

View all

Supplier onboarding in UK construction: lessons from Mobilize

01 Sep 2025Supplier onboarding & supply chain management in UK construction: how to automate PQQs, manage compliance, avoid expiry risk, and what Mobilize (by Liaison Systems) delivers.

The Future of Procurement & Supply Chain Management in Construction After the UK’s 2025 Budget

08 Dec 2025Explore how the UK’s 2025 Budget is reshaping procurement and supply chain management in construction. Learn about digital compliance, ESG obligations, SME onboarding, resilience monitoring, and real-time supplier performance—and how Mobilize supports the industry’s future.

Use Mobilize to give Suppliers the Visibility & Control they’ve Always Wanted

01 Dec 2025Most supply chain platforms offer little transparency. Mobilize, from Liaison Systems Ltd, is different. Originally built to streamline contractor procurement, Mobilize has evolved into a tool that empowers suppliers just as much as contractors.